Your contractor needs to have all the important points on rates including work charges, warranty data, components prices, and price savings from power effective units.

After having a quality installation, maintenance is the key to an extended and of use living for an HVAC unit. Alongside guarantees and assures on installation careers, some companies offer preservation options and regularly planned support calls to keep your system operating frustration free. Standard maintenance can keep points working easy and save money over the life span of one’s unit. Choose a contractor that specializes in the models they support and replace. Choosing a contractor for the next AC Installation Fayetteville NC work doesn’t have to be always a time consuming ordeal. Use these 5 details to assist you select the best organization for the job.

Among most of the components of any industrial HVAC installment, centrifugal pushes are one of the most vital. They help cooling systems, boilers, water programs, hydronic methods, and chillers. The centrifugal pump effectiveness of a commercial HVAC system depends how properly the push is managed, how well the push and engine function, and how properly maintained the push and the other heat and air-con parts are. However sends have built modest changes over the years, they are still essentially exactly like they actually were. Nearly every important part of any commercial HVAC installation has been greatly revised to be power effective and more effective. Centrifugal pumps, nevertheless, have just built small changes in style, structure, and material.

It is just recently that the matter of centrifugal push performance has been raised. Now that improvements are increasingly being created by way of high effectiveness pushes and get motors, less power is required to use them. Along with these recent upgrades, more complex and precise push regulates are increasingly being presented into industry which are giving newer professional HVAC systems an advantage on the old systems. Although the power usage for the pump is reduced, it is applied constantly, meaning that also slight changes in design and performance might have substantial influences on energy costs.

The newer controls on centrifugal pump types can help influence the flow of water in air conditioning and heat appliances. Variable frequency pushes are now actually able to control pushes for a variety of conditions arising from the utilization of a professional HVAC. For the average commercial HVAC installation, an upgraded centrifugal push with variable volume drives preserves anywhere from thirty to fifty percent on energy usage on the span of a year.

Smart push controllers are a new enhanced edition of pushes for professional HVAC applications. Smart controllers may be connected around watches the big event of the push and can alert to malfunctioning areas or a damaged centrifugal pump. They can be set ahead of time to over come popular problems and home regulate themselves without halting heating or air con functions.

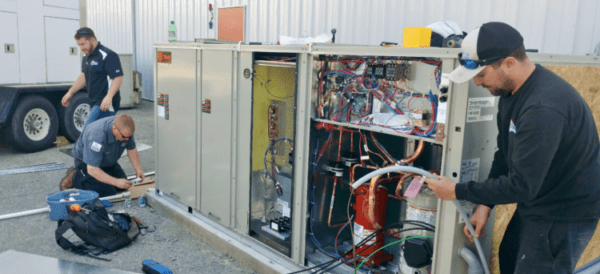

Even though pushes are now being increased, standard preservation is still necessary. If preservation is delay, the function of the push might fail and trigger injury to the system. Maintenance professionals should be experienced to work well with variable frequency drives and sensible pump controllers in order to hold them working efficiently. If an HVAC contractor is new to the application used for the newer versions they will maybe not have the ability to check always for difficulties with calibration and function.

The centrifugal push should be frequently examined for abnormal purpose or failure. When it is making unusual disturbances or vibrations it might suggest so it must be repaired. After a pump reaches the end of their life, preservation professionals should determine why the pump wore out. If they just replace the push without determining the reason why behind why it unsuccessful, the brand new push might well crash, too. Causes for a pump failing are bad style, a problem in the push it self, poor treatment and maintenance, and improper operation.