Generally, the word conveyor is explained as a device that transports a product from one point to another. Adding mechanized and computerized operations to such devices conceptualized paint finishing systems. Most production industries adapted the technology within their respective assembly lines. Automated conveyor systems are created to deviate from the essential applications of the alleged rolling-pin conveyors. Automation is very substantial for weightier transportations and transmissions. In certain scenarios wherever conversation with assembly lines are encouraged, automation is going to be of great help. Look into the numerous subclasses and different employs for these conveyor technologies.

You can find five well-known subcategories for computerized conveyors. First on the list is really a pneumatic conveyor that employs compressed air and vacuum pipes to make the program operate. Next may be the moving conveyor which will be developed in order to transfer risky items from one region to another. That technology has the capacity to sort out the items before they are sent to another end.

The strip conveyor is another popular subclass for computerized conveyor systems. The technology operates with the current presence of looped metal devices and rubber links. These are popular in shifting airport luggage. There’s also a sequence conveyor that is frequently found in the automotive industry. It works with a sizable sequence that rotates between two lever wheels. The screw conveyor is the fifth kind and is appropriate in water programs for agricultural needs. The screw in this conveyor technology form makes the production benefit transportation of varied materials.

Apart from the industries served by the many types of automated conveyors, you will find however other purposes for the industrial product. Generally, it’s applied in order to simplify information procedures in most aspects of operation. This means that it has the capability of resolving problems on manual transportation of goods. With automated versions, you can find you can forget complications in performing the projects in production. These systems are highly ideal than other subcategories of mechanized technologies in that they are better to cope with and no longer require firm instruction for operation.

But there’s one portion a business must observe in making computerized conveyor techniques perform and that is to undergo program maintenance. If this may maybe not be met, use and split of the system will be inevitable. Typical washing of the conveyors and changing the ruined areas are crucial in the preservation process.

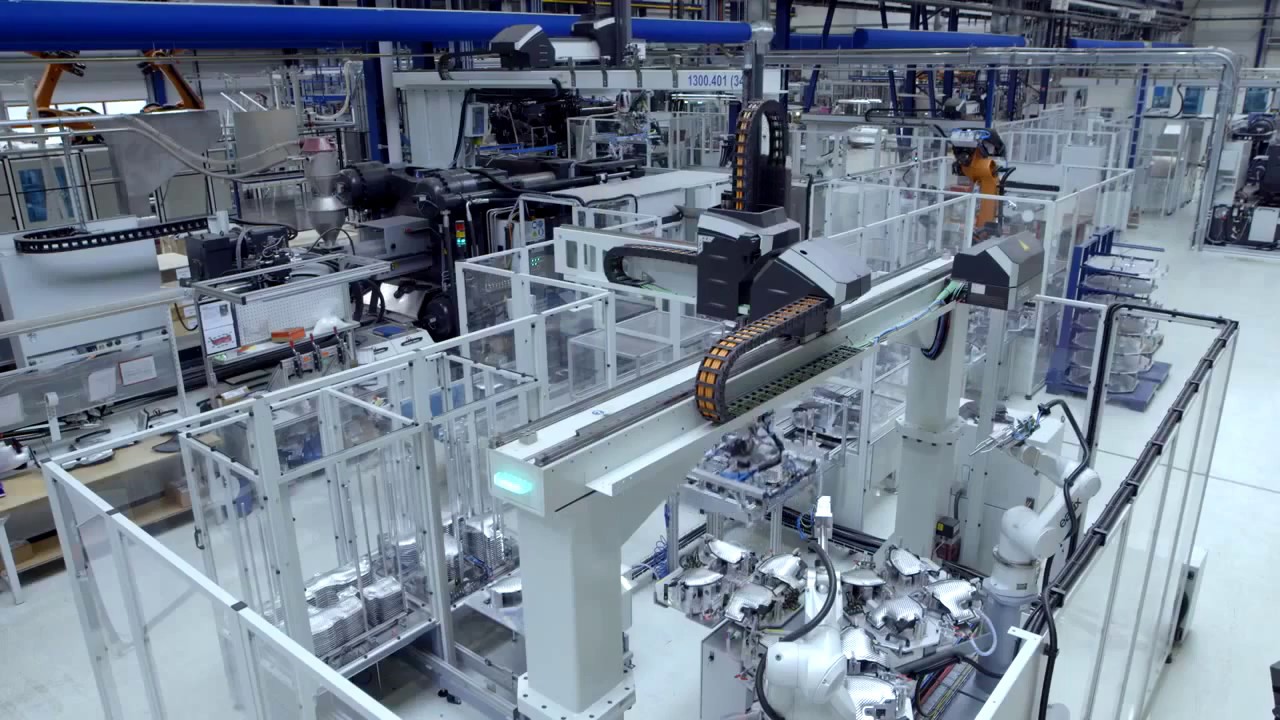

Computerized conveyor programs are now being increasingly found in different industries for the safe transport of materials because they minimize individual labor and increase efficiency. A belt conveyor process is simple to install in a factory and is a lot easier to work when compared to a forklift and other similar large machines. It may be used to go all sorts of masses regardless of fat, size and shape.

Automated conveyors can be run with minimal amount of direction during all adjustments, breaks and weekends. By using these conveyors, you save your self punctually missing as a result of worker lateness and absenteeism. More over, the scope for human problem is less and the proper products are quickly provided to their intended areas in a smooth manner. Automatic conveyor programs are best suited for high frequency shipping schedules. By using computerized conveyors, you can reduce product and solution reduction because of inconsistent handling, breakage and employee inattention.

The repeated character of the job contributes to the tedium that workers can experience during efficiency of particular tasks. This could result in individual problems causing big losses. If you want accuracy and repeatability, automation is your very best bet to produce high-quality effects time and time again. Employee satisfaction is also guaranteed in full due to the level of comfort given by ergonomically developed automated conveyor techniques that minimize the need for workers to do physically challenging tasks.

Warehouses that use Conveyor Programs will not need to utilize a big number of employees. There’s a lowered dependence on personnel since the conveyors may do the work of numerous employees. Organizations can cut down fees and cut costs on individual reference management, paycheck, government costs and employee training programs. That is vital in a financial circumstance that doesn’t search too promising for the future.